I don't believe these are the Samsung diodes, but rather Nichia (NT2L757GTR-V1 80/90 mix). From what I can find. If that makes any difference.

Are you saying now that using one qb324 board would draw only 70-80w at 1400ma, not 150w?

Just trying to be clear before I take the time to assemble a frame and wire them up. Thanks for all the input guys.

It depends on how they are wired. If they are 18S18P then it'll be ~51V board but if they are wired 36S9P then you'll need twice the voltage, so it'd be ~102V board with 36S9P. Voltages will increase as you brighten, decrease as you dim, so it'll be somewhere in there depending. Also trace resistance and wire resistance ect adds to the total voltage needed so it'll be a bit higher generally.

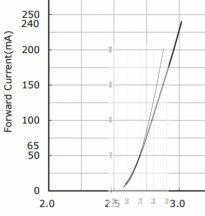

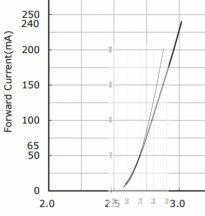

The LM301B and Nichia 757 v3 are about identical in how they react to current, below is an overlay of a 757 v3 (longer) and a LM301b (shorter), the 757 v3 looks like it needs a bit more voltage to flow the same current but pretty close and the overlay isn't exact..

So look on the board for a 18P18S or 36S9P marking, most boards have a basic SP label.

Mid power chips will typically only be rated for 3.0V. So you can use 3.0V as a generic number when guesstimating regardless of chip brand. Find the number in the SP label referring to the number of chips in series and multiply that S number by 3.0V to get what voltage you'll need. X amount of chips in series multiplied by 3.0V per chip.

If the board is wired 36S9P then current gets divided 9 ways. So 1400 ÷ 9 = 155mA. 155mA per row means 155mA per chip because the 36 chips in the row are wired in series which means that current stays the same throughout each chip along the 36 chip series pathway. At 155mA each chip will correspond to about 2.9V (look at graph), so the board would need, 104.4V (36 chips × 2.9V). Watts equal V × A, so 1.4A total × 104.4V = 146.6W. ... ...Now that's an exact number but calculated from a bunch of estimated or extrapolated figures from graphs etc, so real world will be close but will always wiggle a bit from calculated properties.

If the board was 18P18S, then 1400mA divided by 18 rows equals 78mA per 18 chip string. Looking at where V correlates at 78mA for a 757 v3 we notice about 2.75V per chip is needed to flow 78mA, so the total board V is 49.5V. Watts = V × A, so 49.5V × 1.4A = 69.3W

If you can't find a SP label then you could plug the 324 into the 240h 1400 by itself, and measure the voltage with a multimeter. Or you could just try to add them all on like they were 50V boards and if it doesn't fire then they are 110V boards. If they fire it means 50V boards and 70 w per board, if they don't fire it means they are 110V and 1 will draw 150W at 1400mA.

EDIT:

Oops you said 757 v1 not v3, which will probably require a tad more voltage per chip over the v3, but still be pretty same ballpark, at 18 chips or 36 chips and only a .05V difference in forward voltage, you'll be within a volt or 2 of each other