Grow Tent and Light Shopping

- Thread starter High kev

- Start date

Armdog

RDWC GROWER

I use the qb288. If you are using anything else you can probably get by with your configuration.Just trying to save you some money. You can still do your configuration but you will have to watch that you don’t light burn them. You would also have to add C02 to get the benefit over 1000 par.

Last edited:

Armdog

RDWC GROWER

They are super easy to wire. Use series method and not parallel. If you have a board go out in parallel it could force the remaking voltage to the other boards causing failure or fire from what I was told . Positive to negative. HLG has a great tutorial on their site.Ty for your help these lights are a whole mother animal with all these numbers and letters I barley made it out of highschool. If I would have known that lights were going to get this complicated I would have studied harder

Armdog

RDWC GROWER

Look at post 282 and see which boards you are usingTy for your help these lights are a whole mother animal with all these numbers and letters I barley made it out of highschool. If I would have known that lights were going to get this complicated I would have studied harder

Armdog

RDWC GROWER

You should be ok, just keep an eye on the centerI’m using 132. 3000k and 4000k combo

Armdog

RDWC GROWER

I thought you were using 3000k and 3500k. 3000k is sufficient for veg and flower.I’m using 132. 3000k and 4000k combo

Armdog

RDWC GROWER

Just use them allI ordered both was going to mix them. Stagger and mix them maybe I can use two power cords and turn off the 3000k for veg than on for when they’re flowering idkthese lights have my head spinning lol

Bruno8437

Super Active Member

I agree. Use as much light as your plants will take.Just use them all

Big Perm

Budtender

If running parallel on multiple boards, you should put an in-line fuse on them for about 1 amp above, better to blow the fuses than have thermal runaway.They are super easy to wire. Use series method and not parallel. If you have a board go out in parallel it could force the remaking voltage to the other boards causing failure or fire from what I was told . Positive to negative. HLG has a great tutorial on their site.

An in-line fuse is a good idea, either way.

Armdog

RDWC GROWER

I have read that it is not a good idea to run these boards in parallel. They say it can cause what is called runaway if one board fails. Just what I have read.If running parallel on multiple boards, you should put an in-line fuse on them for about 1 amp above, better to blow the fuses than have thermal runaway.

An in-line fuse is a good idea, either way.

Big Perm

Budtender

I agree. People with not much DIY experience probably shouldn't run parallel.I have read that it is not a good idea to run these boards in parallel. They say it can cause what is called runaway if one board fails. Just what I have read.

MtRainDog

Blümen Meister

I have read that it is not a good idea to run these boards in parallel. They say it can cause what is called runaway if one board fails. Just what I have read.

Like you said, adding a fuse is a good idea.I agree. People with not much DIY experience probably shouldn't run parallel.

That said, you don't need to be scared too much by the idea of running parallel so long as you understand and follow certain safety precautions.

The best thing you can do is perform regular inspections of your equipment. Since we all like to ogle our plants all the time, take this time to make sure all your connections are holding firm and that your components aren't getting too hot. I do this every time I enter my grow room.

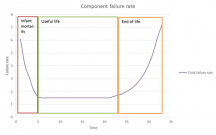

Yes, a board could possibly fail for an unknown reason (faulty board, etc.) but we should put this into perspective. The life span of electric components is described by the MTBF funciton (Mean Time Before Failure).

Basically, it's a graph that looks like this, we call it a "bath tub" curve in the statistics world.

What this shows us is that most electronic components will either fail very early on in life (a truly faulty device) or they will live on into their expected end of life. You can see, not many fail in between. If we graphed these for quantum boards or some other quality LED setup, we would be graphing failures over years, as most of these should live on without issue for several years. Not to mention HLG performs initial tests before these things leave the factory catching most of the faulty devices.

All that is a fancy way of saying if it's faulty, it will fail early on.

So if it's not faulty, and it's not nearing it's EOL, then what do we need to be worried about? Mainly I would worry about connections coming loose somehow. This is why again you should be performing regular inspections of your equipment.

Last edited:

Big Perm

Budtender

Exactly. All of my Amare and iLuminar lighting is wired in parallel from production.That said, you don't need to be scared too much by the idea of running parallel so long as you understand and follow certain safety precautions.

Big Perm

Budtender

Series and parallel are 6 one way, half a dozen the other. What changes is voltage and amperage, watts stay the same. Similar to comparing 110v to 220v.

In series you would have the same problem if a board smoked. The other boards' wattage would go up just like it would in parallel. The thermal runaway is rare. Even though no one uses them, fuses but equal wire lengths are important in parallel, especially on longer runs.

In series you would have the same problem if a board smoked. The other boards' wattage would go up just like it would in parallel. The thermal runaway is rare. Even though no one uses them, fuses but equal wire lengths are important in parallel, especially on longer runs.

MtRainDog

Blümen Meister

Good info there too, especially on the equal length wires, I believe it's the resistance (ohms) that change depending on the wire length. I think for runs under a couple feet the difference between your longest and shortest runs wouldn't be significant enough to cause harm (i'm sure there's a calculator somewhere online).Series and parallel are 6 one way, half a dozen the other. What changes is voltage and amperage, watts stay the same. Similar to comparing 110v to 220v.

In series you would have the same problem if a board smoked. The other boards' wattage would go up just like it would in parallel. The thermal runaway is rare. Even though no one uses them, fuses but equal wire lengths are important in parallel, especially on longer runs.

Still a very good idea as a best/safe practice. I would think the driver would monitor ohms/amps/volts, and turn off if they got out of safe operating range. It's a basic safety requirement of devices like this, and is why the driver will turn off/on if the voltage is set too high.

What you're mostly trying to avoid is a short, where resistance drops too far low, and things go pop and smoke. Usually this happens suddenly, like if something snags a wire and pulls it loose. Eyeball these things everyday and don't be lured in to a false sense of confidence.

Big Perm

Budtender

Good post.I would think the driver would monitor ohms/amps/volts, and turn off if they got out of safe operating range.

You could fry your whole setup and the driver would still stay in range, though. If one board/strip/cob, etc. went, everything from the driver would stay the same, the other lights would then take that wattage. Over time it would take out your whole setup.

Edit: unless you had fuses

Big Perm

Budtender

I gotta see thisFuses here we come